Optional Products

- Plastic box

- PP box

- PET box

- Clear box

- PVC box

- Clamshell Packaging Box

- Clear cylinder packaging

- Food Packaging Box

- Tube Packaging

- Printed box

- PET plastic box

- PET box for foods packing

- Clear plastic folding boxes

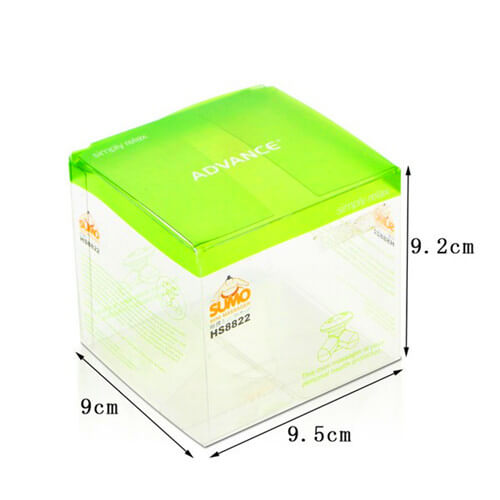

- Cube box

- Crystal clear packaging

- Clear PVC box

- Hanging box

- Clear plastic box for cosmetic

- Egg tray

- Box design

- Toy packaging

- Plastic packages

- Packaging box

- Packaging for food

- Custom packaging

- Clear plastic box

- Transparent plastic box

- Transparent box

- Clear folding box

Plastic clear cylinder packaging | clear cylinder box | Transparent cylinder container

To have your best quality and best looking customized clear cylinder packaging, please contact us today.

Material: (PVC, PET, PP), material with excellent transparency.

– Clear cylinder packaging can be made as per customer’s request and design.

– Clear cylinder packaging can be made of different thickness of the material, with different size, different printing and design.

– Excellent quality and competitive price.

Help You To Design

We can help you to design good looking impressive packaging.

Commitment Good Quality

Certified by ISO 9001, ISO 14001, FDA, ROHS, GMP. With leading quality.

Competitive Price

Offer you the super competitive prices for good quality packaging

Product name: Plastic clear cylinder packaging | Material: PP, PET, PVC, PS, etc | Plastic type option: 100% vigin / recycled plastics |

| Usage: to pack different types products | Colour: Clear / Printed | Size: Customized to fit your products |

| Design: Customized good looking designs | Country of origin: China | Certificate: ROHS, SGS, ISO, FDA (for foods pack) |

| MOQ: 1000 PCS/design | Delivery time: 4 days | Sample: available, sample is free |

Our clear cylinder packaging is the beautiful packaging made by high quality plastic.

Plastic is a class of multi-performance, multi-species synthetic materials, plastic as a packaging material, has greatly changed the entire face of commodity packaging. We have created an unprecedented variety of new and unique packaging container.

Basic properties and characteristics of clear cylinder packaging made from plastics

(1) Excellent physical properties.

Plastic has a certain strength, elasticity, tensility, compression, impact, bending, folding, friction, moisture, gas barrier and so on. .

(2) Good chemical stability.

Plastics are resistant to acid and alkali, chemicals, grease, rust and corrosion.

(3) Plastic is a lightweight material.

Plastic specific gravity of about metal 1 / 5, glass 1/2, in line with the direction of lightweight container box.

(4) Plastic processing and forming a variety of simple materials.

Plastic can be made into films, sheets, tubes, strips, but also woven cloth, used as foaming materials, etc., the molding methods are blow molding, extrusion, extrusion, and so on. The use of a variety of new technologies such as injection molding, casting, vacuum, foaming, blistering, shrinking, stretching and the application of a variety of new technologies can create a product that is suitable for a variety of applications. New type of packaging needed.

(5) Plastic has excellent transparency and surface gloss, good printing and decorative performance.

Good effect can be achieved in conveying and beautifying products.

(6) Plastic is an energy-saving material, prices have a certain degree of competitiveness.

Plastic as a packaging material also has shortcomings: strength as iron and steel, heat resistance is not as good as glass, in the external factors under the long-term effect of easy to occur aging.

Some plastics are not absolutely impermeable to air, light or moisture.

Classification of clear cylinder packaging plastics

Many methods of classification of plastics, according to their heat processing performance characteristics, can be divided into thermoplastic and thermosetting plastics of two categories.

More of the former is a soft material, which is a rigid molding material.

clear cylinder packaging of plastics and more belong to the thermoplastic.

View more designs

We are an excellent plastic clear cylinder packaging manufacturer, wholesaler

Clear cylinder packaging are widely used for hardware, daily-use tools, medicines, gifts, cosmetics, foods, stationery, electronics and toys etc.

We are a leading Clear cylinder packaging supplier, Clear cylinder packaging manufacturer, with more than 25 years experience.

Firstly, we can provide the clear customized box with excellent quality and competitive price.

Secondly, our clear box has many types of designs for your option. You can always find the clear cylinder packaging that suits your products from us.

Our factory is specialized in making plastic boxes & plastic cases, clear plastic folding boxes, PVC boxes, PET boxes, and plastic PP Boxes. We have been producing and wholesaling clear plastic boxes for many retail industries.

Our company is one that has been in business for almost two decades and has some fortune 500 companies as our customers. The customers are satisfied with the good quality packaging and service.

You will be satisfied as well.

Contact Us now to request a quote or free sample for more high-quality and good price plastic boxes.

Our products are widely used for hardware, daily-use, medicines, gifts, cosmetics, foods, stationery, electronics and toys etc. We can provide higher quality products, more competitive price, timely delivery.

Printing Options:

– Offset printing

– Silk-screen printing

– Foil stamping

– Hot-stamp

– Other special effects printing

Sample lead time:

Usually, 3 days to make the sample.

Production lead time:

Usually, 100 thousand pieces clear box in 3 days.

certification:

Clear cylinder packaging ISO 9001, ISO 14001, OHSAS 18001, FDA, GMP, RoHS, REACH, SGS

Plastic cylinder packaging is produced mainly by plastic material PVC or PET

PVC material is polyvinyl chloride. It is one of the largest plastic products in the world. It is cheap and widely used. Polyvinyl chloride resin is a white or light yellow powder. PVC is a white powder with an amorphous structure, with a small degree of branching and poor stability to light and heat. Different additives can be added according to different purposes, and polyvinyl chloride plastics can exhibit different physical and mechanical properties. Adding appropriate amounts of plasticizer to polyvinyl chloride resin can be made into a variety of hard, soft and transparent products.

Polyvinyl chloride has good electrical insulation properties, and can be used as a low-frequency insulation material, and its chemical stability is also good. Due to the poor thermal stability of polyvinyl chloride, heating for a long time will cause decomposition and release of HCl gas, which will cause the polyvinyl chloride to change color. Therefore, its application range is narrow, and the operating temperature is generally between -15 to 55 degrees.