Optional Products

- Plastic box

- PP box

- PET box

- Clear box

- PVC box

- Clamshell Packaging Box

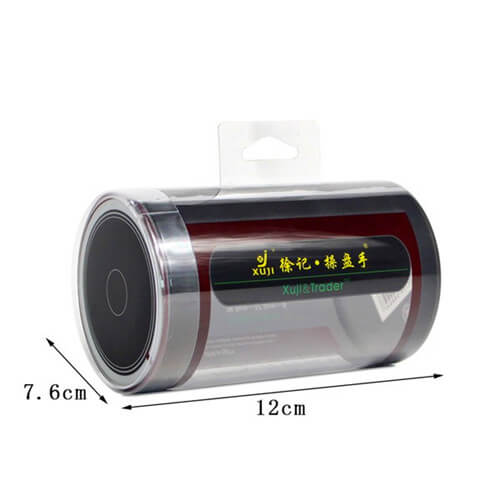

- Clear cylinder packaging

- Food Packaging Box

- Tube Packaging

- Printed box

- PET plastic box

- PET box for foods packing

- Clear plastic folding boxes

- Cube box

- Crystal clear packaging

- Clear PVC box

- Hanging box

- Clear plastic box for cosmetic

- Egg tray

- Box design

- Toy packaging

- Plastic packages

- Packaging box

- Packaging for food

- Custom packaging

- Clear plastic box

- Transparent plastic box

- Transparent box

- Clear folding box

Clear PVC box | Transparent clear PVC box | Clear PVC packaging box

To have your best quality and best looking customized clear box, please contact us today.

Help You To Design

We can help you to design good looking impressive packaging.

Commitment Good Quality

Certified by ISO 9001, ISO 14001, FDA, ROHS, GMP. With leading quality.

Competitive Price

Offer you the super competitive prices for good quality packaging

Product name: Clear PVC box | Material: Transparent clear PVC | Plastic type option: 100% vigin |

Usage: to pack different products | Colour: Clear / Printed | Size: Customized to fit your products |

| Design: Customized good looking designs | Material thickness: Customized | Certificate: ROHS, ISO, FDA (for foods pack) |

| MOQ: 1000 PCS/design | Delivery time: 4 days | Sample: available, sample is free |

What’s the clear PVC box’s Features & Benefits?

- Clearly, items inside can be seen clearly.

- Protected and great quality plastic material

- Produced using top-grade, scratch safe, clear plastic material

- Delicate innovation makes packaging straightforward and simple

- High effect safe definition implies they won’t break or become weak

- Hostile to static plastic decreases static energize fabrication

- Save money on goods delivery and capacity costs

In Fortune Packaging, we use high quality manufacturing raw materials for your clear PVC box packaging

The choice of clear PVC box’s raw material should take into account the following three aspects at the same time:

It must ensure that the packaged products can finally reach the consumers in good quality after going through all aspects of circulation and sales.

It must meet the requirements of packaging costs, economically feasible.

It must take into account the economic interests of manufacturers, transportation and sales departments, and consumers, making it acceptable to all three parties.

In Fortune Packaging, when designing and manufacturing clear PVC boxes, we seriously study the reciprocity of packaging materials and packed goods.

The packaging materials used vary greatly depending on the type, properties and price of the packaging.

Valuable packaging materials generally use high-end packaging materials with good performance. The main consideration is to ensure that the packaging is well protected to ensure the safety of the circulation. As for the packaging materials and operating costs, it is a secondary issue.

As long as the general packaging is based on its type, size and weight, it is necessary to reduce the cost of packaging materials and packaging operations and facilitate unpacking operations, so as to select appropriate packaging specifications and packaging materials.

Daily necessities and toiletries are mostly low-grade commodities, and care should be taken to reduce the cost of packaging materials, packaging operations and transportation costs. Make consumers feel economical and practical, genuine.

Since we want to retail through the market, we must try to reflect the decoration function and shelf function on the outer packaging.

In order to meet the needs of a specific consumer layer, there should be some high-end products, whose functions are not very different from those of low-end products, but the impressions given to consumers are significantly different, that is, in single packaging

The materials and printing quality of the packaging and outer packaging strive for luxury, and the packaging container used must have a thick sense, giving people the feeling of high-grade goods, without having to worry about the packaging cost.

In short, in terms of packaging materials and printing modeling, satisfying the psychological requirements of consumers at different levels is the first.

In Fortune Packaging, when designing and manufacturing clear PVC boxes, we carefully study the coordination of packaging materials and packaging categories and units.

Inner packaging and outer packaging have different protective effects on the packaging.

Which aspect of a certain packaging material can fully exert its packaging function must be carefully discussed.

The materials used in the single packaging are in direct contact with the packaging, so the materials for the single packaging must be able to protect the quality of the packaging.

Often used are flexible packaging materials, such as plastic films, paper, and composite materials.

When choosing material, if a single layer of material can meet the needs, use a single layer of material. If the single-layer material cannot meet the requirements, the multi-layer composite material is used.

The inner packaging is located between the single packaging and the outer packaging, and has the dual functions of decoration and cushioning. It mainly uses cardboard, processed paper and other materials.

The requirements are suitable for decorative printing, the surface is shiny, easy to machine, easy to fill, easy to seal, etc.

The outer packaging is the outermost packaging of the package. In addition to the decoration and cushioning requirements, it also can withstand the impacts and tears that occur during transportation.

Rigid PVC plastic packaging materials are often used.

We are a leading clear PVC box manufacturer. Packaging: Clear PVC box | Clear PVC boxes for gifts

We’re a leading PVC box supplier in China, with more than 25 years experience with clear box.

Firstly, we can provide the clear box with excellent quality and competitive price.

Secondly, our Clear PVC box has many types of shapes and styles, you can always find the clear box that suits your products.

Our factory is specialized in making plastic boxes & plastic cases, clear plastic folding boxes, PVC boxes, PET boxes, and plastic PP Boxes. We have been providing wholesale clear plastic boxes for many retail industries.

Our PVC Boxes company is one that has been in business for almost two decades and has served more than a few of the fortune 500 companies. L’Oreal, Nivea, Starbucks etc. and have a very happy and long-term cooperative relationship with these customers.

We’re highly trusted by these names and they never hesitate to offer their gratitude for our services of PVC boxes. So, if the top companies are using our services, that’s a clear sign that maybe you should as well.

Contact Us now to request a quote or free sample for more high-quality and good price plastic boxes.

Our products are widely used for hardware, daily-use, medicines, gifts, cosmetics, foods, stationery, electronics and toys etc. We can provide higher quality products, more competitive price, timely delivery.

Printing Options:

– Offset printing

– Silk-screen printing

– Foil stamping

– Hot-stamp

– Other special effects printing

Sample lead time:

Usually, 3 days to make the sample.

Production lead time:

Usually, 100 thousand pieces clear box in 3 days.

certification:

ISO 9001, ISO 14001, OHSAS 18001, FDA, GMP, RoHS, REACH, SGS

Clear PVC boxes are produced mainly by plastic material PVC

PVC material is polyvinyl chloride. It is one of the largest plastic products in the world. It is cheap and widely used. Polyvinyl chloride resin is a white or light yellow powder. PVC is a white powder with an amorphous structure, with a small degree of branching and poor stability to light and heat. Different additives can be added according to different purposes, and polyvinyl chloride plastics can exhibit different physical and mechanical properties. Adding appropriate amounts of plasticizer to polyvinyl chloride resin can be made into a variety of hard, soft and transparent products.

Polyvinyl chloride has good electrical insulation properties, and can be used as a low-frequency insulation material, and its chemical stability is also good. Due to the poor thermal stability of polyvinyl chloride, heating for a long time will cause decomposition and release of HCl gas, which will cause the polyvinyl chloride to change color.