PP box we can design for you

We produce your packaging with love and passion

Helping Fortune 500 companies and you

Optional Products

- Plastic box

- PP box

- PET box

- Clear box

- PVC box

- Clamshell Packaging Box

- Clear cylinder packaging

- Food Packaging Box

- Tube Packaging

- Printed box

- PET plastic box

- PET box for foods packing

- Clear plastic folding boxes

- Cube box

- Crystal clear packaging

- Clear PVC box

- Hanging box

- Clear plastic box for cosmetic

- Egg tray

- Box design

- Toy packaging

- Plastic packages

- Packaging box

- Packaging for food

- Custom packaging

- Clear plastic box

- Transparent plastic box

- Transparent box

- Clear folding box

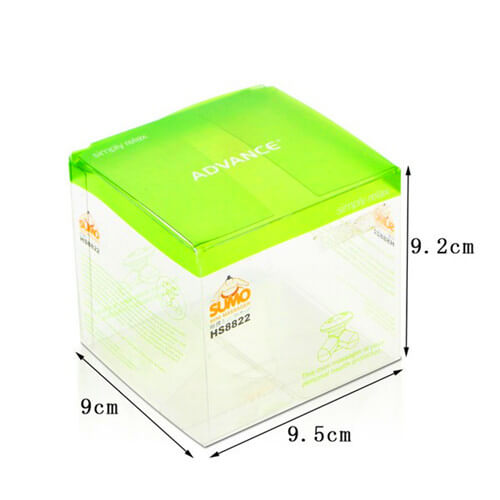

PP box, translucent pp box, clear pp box

To have your best quality and best looking customized PP box, please contact us today.

Product name: PP box | Material: PP | Plastic type option: 100% vigin |

| Usage: to pack different types products | Colour: Clear / Printed | Size: Customized |

Design: Customized good designs | Material thickness: Customized to fit product | Certificate: ROHS, ISO, FDA (for foods pack) |

| MOQ: 1000 PCS/design | Delivery time: 4 days | Sample: available, sample is free |

Help You To Design

We can help you to design good looking impressive packaging.

Commitment Good Quality

Certified by ISO 9001, ISO 14001, FDA, ROHS, GMP. With leading quality.

Competitive Price

Offer you the super competitive prices for good quality packaging

The manufacture and design of our PP box is based on the important premise of protecting natural resources

We continue to invest capital and use more talents to improve and improve the technology of producing PP box.

Reasonable use of natural resources is an important way to improve the economic and social benefits of packaging enterprises.

Packaging production enterprises use modern scientific and technological achievements to make full use of natural resources, which not only has a direct impact on ensuring product quality and reducing costs, but also has an important role in preventing environmental pollution and maintaining ecological balance.

The state of natural resources has a very close relationship with the development of packaging.

Packaging is closely linked to the consumption of natural resources.

Environmental protection is an important prerequisite for our box packaging mady by PP.

The close relationship between packaging and environmental pollution and the protection of ecological balance is mainly manifested in the public hazards caused by two aspects.

That is, the pollution of the packaging industry and packaging waste to the environment.

Exhaust gas, waste water and waste residues from industrial processing of packaging materials, and some auxiliary materials contain a variety of inorganic and organic substances.

Toxic chemicals and harmful microorganisms contained in unrecycled waste cause environmental pollution, increase industrial pollution, and increase the damage to the ecological balance.

Therefore, we attach great importance to the correct handling of environmental protection issues in packaging manufacturing, taking into account the unity of economic, social and ecological benefits.

With the development of the economy and the continuous improvement of people’s lives, the demand for PP box packaging is increasing, and the waste after packaging has also increased accordingly, which has become an important cause of garbage pollution.

The disposal of garbage after packaging is a tricky problem.

It can cause harmful chemicals to pollute the soil and groundwater: some materials are difficult to decompose, and once washed into the rivers and lakes by rainwater, it will cause harm to some aquatic animals.

Some harmful substances released into the air will form a “secondary pollution”.For example, acid-forming compounds will form acid mist, acid rain, lower the pH of soil or lake, endanger ground plants and aquatic organisms, and affect the production of crops and aquatic products. Some toxic gas substances are produced by human breathing and skin contact danger.

Therefore, we are committed to research and adopt environmentally friendly PP boxes to promote the development of packaging.

What’s the PP box’s Features & Benefits?

- Clearly, a special transparency with little foggy style

- Protected and great quality plastic material

- Produced using excellent, scratch safe clear plastic material

- Delicate collapsing innovation makes get together straightforward and simple

- High effect safe detailing implies they won’t break or become weak

- Hostile to static plastic decreases static energize assemble

- Lead and sans phthalate

- Stores and ships level to save money on delivery and capacity costs

We are a leading PP box factory for translucent pp box, clear pp box.

We’re a great provider, producer of the plastic packaging box, accessible for box design, with very 25 years experience.

The PP box is light in weight and has high quality. These are its greatest points of interest. We’ll structure the container that precisely accommodates your item for you, making your item progressively alluring in our bundling box. We’ll do the crate structure for you. We are the main scholars about innovation and craftsmanship. We produce great redid boxes for you. For the most part, the materials utilized for clear boxes are PVC/PET/PP, and so on. We are a provider for a few well known worldwide brands and furthermore the world’s best 500 organizations. We’ll make a crate plan for all clients.

Our production line is spent significant time in making plastic boxes and plastic cases, clear plastic folding boxes, clear box, printed box, PVC boxes, PET boxes, and plastic PP Boxes. We’ve been delivering and wholesaling clear plastic boxes for a few retail ventures.

Contact us now to get a design or free example for all the more high-caliber and great value plastic boxes.

Our items are broadly utilized for equipment, medications, beautifying agents, nourishments, writing material, gadgets, and toys, and so forth.

Printing Options:

– Offset printing

– Silk-screen printing

– Foil stamping

– Hot-stamp

– Other special effects printing

Sample lead time:

Usually, 3 days to make the sample.

Production lead time:

Usually, 100 thousand pieces clear box in 3 daysJus

certification:

ISO 9001, ISO 14001, OHSAS 18001, FDA, GMP, RoHS, REACH, SGS

PP box are produced mainly by plastic material PP

Polypropylene is a polymer produced by the addition of polymerization of propylene. White waxy material, transparent and light in appearance. The density is 0.89 ~ 0.91g / cm3.

Flammable, melting point 165 ° C, softened around 155 ° C, operating temperature range is -30 ~ 140 ° C

It can resist the corrosion of acid, alkali, salt solution and many organic solvents below 80 °C, and can decompose under high temperature and oxidation.

Polypropylene referred to as PP is a colorless, odorless, non-toxic, translucent solid substance.

Polypropylene (PP) is a thermoplastic synthetic resin with excellent properties. It is a colorless and translucent thermoplastic lightweight general-purpose plastic.

With chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high wear-resistant processing properties.

The production process of polypropylene has mainly gone through several development stages including solvent method, solution method, liquid bulk method (including liquid phase gas phase combined type) and gas phase method.

The world’s process methods for the production of polypropylene are divided into the following major categories according to categories: solvent method, solution method, liquid bulk method (including liquid phase gas phase combined type) and gas phase method.